Basic concepts

![]()

![]()

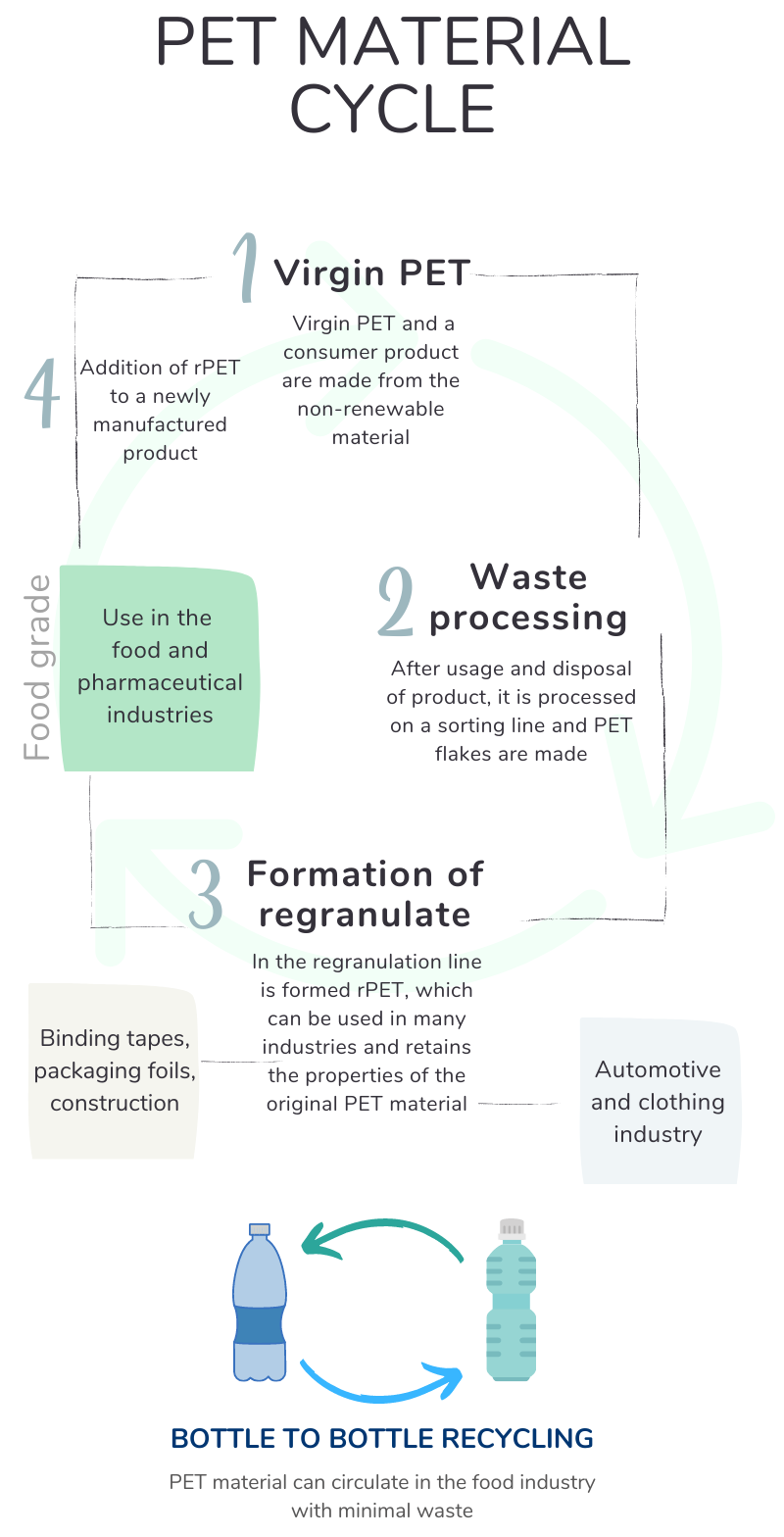

PET = polyethylene terephthalate, a thermoplastic from the polyester group used in the manufacture of fibres, bottles, and other packaging materials

Virgin PET = virgin PET, PET made from oil. Non-renewable resources need to be extracted for its production

rPET = recycled PET, there is no need to extract non-renewable resources for its production

RPET material has various secondary applications, e.g. binding tapes, packaging foils, garden furniture, automotive products, etc. Unfortunately, PET material in excellent quality is often used for these secondary products, but it can also be used in the food industry, especially recycled material made from PET bottles. This product of recycling is a valuable material from which we can produce rPET regranulate. rPET will serve to produce a new PET bottle. We save natural resources.

rPET for food purposes = best (foodgrade) quality

PET is most often used in food production and beverage packaging, and its huge advantage is the possibility of 100% recycling. PET flakes are produced in the recycling companies from sorted PET bottles. These are further processed into rPET regranulate, which can be reused for food purposes in bottle-to-bottle quality. Thanks to a modern process, our technology line can produce rPET regranulate in the foodgrade quality. The production of rPET regranulate in foodgrade quality from recycled material is an important part of the circular economy, as it allows repeatable use of PET material in the food industry.

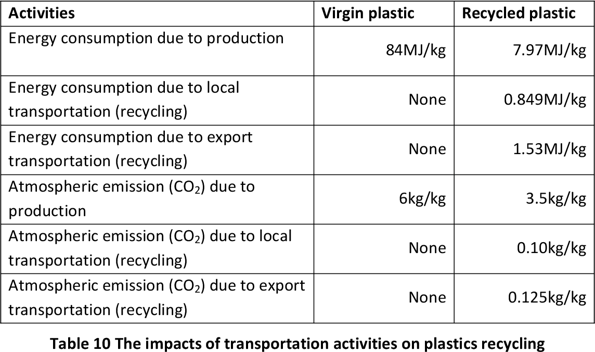

Source: A Study of Plastic Recycling Supply Chain, Wong (2010)